Application background:

The general titanium dioxide output capacity could reach 3.5 million tons, most of which are mainly manufactured in terms of sulfuric acid method titanium dioxide. Plenty of waste acid and waste water are generated during the sulfuric acid method production, if adopt the neutralization method there will be bulk waste plaster precipitated and contaminating the environment.

Treatment:

We offer two proposals for the treatment:

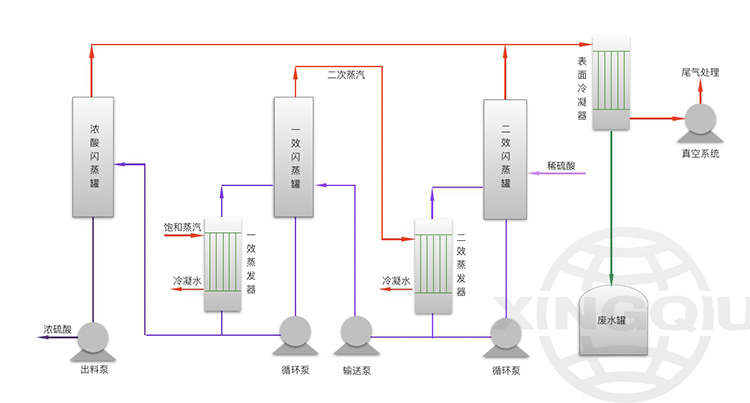

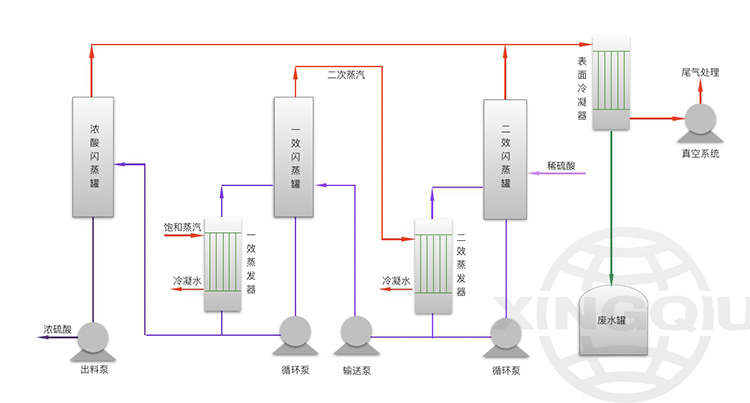

Proposal 1, through the simple low temperature evaporation and concentration method to improve the sulfuric acid consistence.

It adopts dual-effect counterflow and forced circulation plus flashing evaporation process through an adequately utilization of secondary steam to reduce the steam consumption, which is quite suitable for titanium dioxide waste acid treatment.

We choose complete graphite flashing separation tank with working life over 10 years.

Graphite axial waterjet pump is applied in forced circulation mode which saved the cost and improved working life.

The graphite evaporator has improved its heat transfer efficiency and decreased the pressure drop after optimized design.

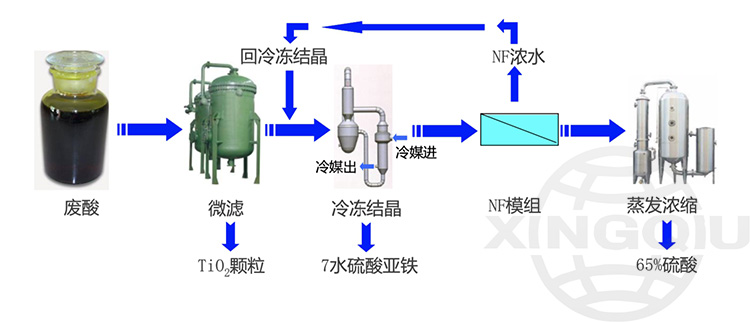

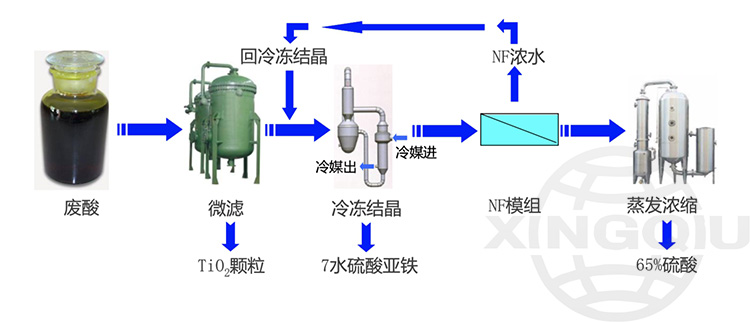

Proposal 2, separate the TIO2 and sulfate from the diluted sulfuric acid through membrane treatment device, then the purified diluted sulfuric acid flows into evaporation system for concentration, which has solved the phenomenon that the evaporator tends to be blocked easily.

Micro filtration is used for TIO2 solids recovery in the waste acid.

The ferrous sulfate is separated through chilling and crystallization.

The ferric ions is concentrated and removed with NF.

Ningbo City Happiness titanium dioxide plant sulfuric acid concentration device